Product added to cart

A4988 Reprap Stepper Motor Driver

$0.7500

In stock

SKU

MTR-09-007

Volume discounts:

- +100 5 % $0.7100

- +300 8 % $0.6900

- +500 9 % $0.6800

- +1000 12 % $0.6600

Product Variations: View out of stock variants

Ships in 2-3 business days, then:

Free delivery in10-15 days by YunExpress on orders over $35.

Free delivery in5-7 days by DHL on orders over $200.

More shipping info

Shop with confidence Learn More

DRV8825 Stepper Motor Driver Module Previous

DRV8825 Stepper Motor Driver Module Previous

The A4988 Reprap Stepper Motor Driver is a widely used and reliable module designed to control stepper motors in 3D printers, CNC machines, robotics, and various precision motion control applications. Utilizing advanced chopper microstepping technology, this driver module enables precise and smooth motor control with adjustable step resolution. Its versatility, ease of use, and compact form factor make the A4988 an essential component for achieving accurate and controlled movement in your projects.

Stepper motors are widely used in robotics, 3D printers, CNC machines, and other automated systems where precise and controlled movement is essential. The A4988 Reprap module serves as an intermediary between the microcontroller or other control circuitry and the stepper motor, translating input signals into precise motor movements.

Key features of A4988 Reprap Stepper Motor Driver Module

The A4988 Reprap Stepper Motor Driver Module boasts several key features that make it a popular choice for controlling stepper motors:

- High Current Capability: The A4988 Reprap can deliver up to 2.5A of current to the stepper motor coils, making it suitable for driving a wide range of stepper motors, including those with higher power requirements.

- Microstepping Support: It supports up to 1/16 step microstepping, allowing for smoother motion and finer resolution compared to traditional full-step or half-step methods. Microstepping divides each full step into smaller increments, enabling smoother operation and improved positional accuracy.

- Integrated Protection Features: The module incorporates various protection features such as overcurrent protection, thermal shutdown, and undervoltage lockout. These protections help prevent damage to the module and the connected stepper motor under fault conditions, enhancing reliability and safety.

- Simple Control Interface: The A4988 Reprap interfaces with a microcontroller or other control electronics using simple step and direction signals. This makes it relatively easy to integrate into various projects and control systems.

- High Efficiency Operation: With its integrated H-bridge MOSFET driver architecture, the A4988 Reprap achieves high efficiency operation, minimizing power losses and heat generation even at high speeds and under varying loads.

- Wide Operating Voltage Range: It supports a wide operating voltage range for motor input, from 8V to 35V, making it compatible with a variety of power supply configurations and stepper motor specifications.

- Compact Form Factor: The A4988 Reprap is available in a compact and space-efficient package, making it suitable for applications where size constraints are a consideration.

- Configurable Current Limit: It features a configurable current limit through a built-in potentiometer, allowing users to adjust the motor current to match the requirements of their specific application.

- Smooth and Quiet Operation: Thanks to its microstepping capability and efficient motor control algorithms, the A4988 Reprap can deliver smooth and quiet operation, minimizing vibration and noise during stepper motor operation.

Overall, these key features make the A4988 Reprap Stepper Motor Driver Module an excellent choice for a wide range of motion control applications, from 3D printers and CNC machines to robotics and automation systems.

Specifications of A4988 Reprap Stepper Motor Driver Module

The A4988 Reprap Stepper Motor Driver Module comes with the following technical specifications:

- Operating Voltage Range: 8V to 35V

- Output Current: Up to 2A per coil (with proper heatsinking)

- Step Resolution: Full step, 1/2 step, 1/4 step, 1/8 step, and 1/16 step

- Built-in Protection Features:

- Overcurrent protection

- Thermal shutdown

- under-voltage lockout

- Logic Voltage (VCC): 3V to 5.V

- Logic Inputs: CMOS/TTL-compatible

- Operating Temperature Range: -40°C to 85°C

- Storage Temperature Range: -40°C to +150°C

- Adjustable Current Limit: Via onboard potentiometer

- Dimensions: 20mm x 15mm x 11mm L x W x H (excluding heatsink and mounting hardware)

- Recommended Heatsinking: There is a heat sink with the module. If you intend to turn on the power close to the rated power for a long time, you should also create proper ventilation in addition to the heatsink.

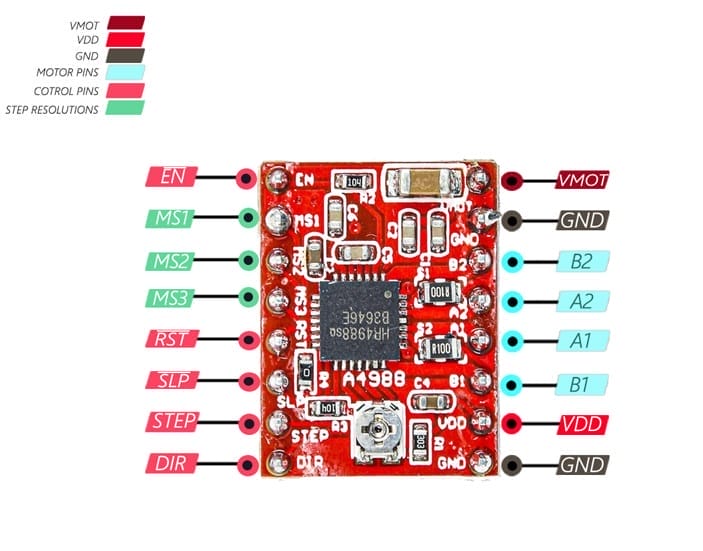

Pinout of A4988 Reprap Stepper Motor Driver Module

- Power Supply Pins:

- VDD: Module power supply – 3-5.5 V

- GND: Ground

- VMOT: Motor power supply – 8-35 V

- Motor Coil Pins:

- 1A:Pin 1 for motor coil 1

- 2A: Pin 2 for motor coil 1

- 1B: Pin 1 for motor coil 2

- 2B: Pin 2 for motor coil 2

- Pins for controlling power states:

- DIR:Digital signal to control the direction of motor movement

- STEP:Digital signal to control rotation steps

- SLP:This signal is used when the motors are not in use – Active-Low

- RST:Reset signal – Active-Low

- EN:When this signal is activated, the driver outputs are disabled.

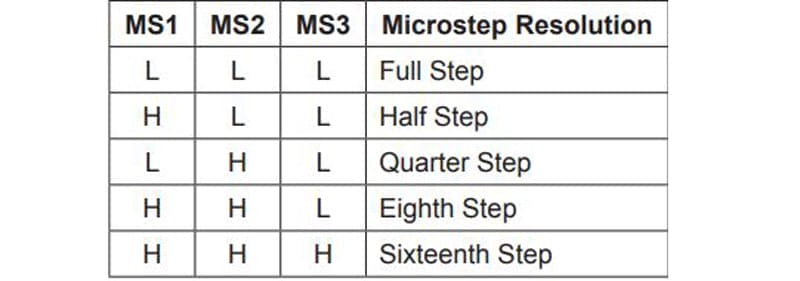

- Step resolution Selection Pins:

- MS1:Step resolution pin 1

- MS2:Step resolution pin 2

- MS3:Step resolution pin 3

-

By changing these 3 pins, you can change the step from full step to step 1/16. The table below shows these changes:

Note: You can use a capacitor to protect the driver from VMOT voltage sparks.

Warning points when using A4988 Reprap Stepper Motor Driver Module

When using the A4988 Reprap Stepper Motor Driver Module, it's essential to be aware of certain warning points to ensure safe and optimal operation. Here are some key considerations:

- Overcurrent Protection: While the A4988 Reprap offers overcurrent protection, it's important to ensure that the motor's rated current does not exceed the driver's specifications. Running the motor at too high a current can lead to overheating and damage to the driver or motor.

- Heat Dissipation: The A4988 Reprap can generate heat during operation, especially at higher currents. Proper heat sinking or cooling measures should be implemented to prevent overheating and ensure reliable performance.

- Voltage Compatibility: Ensure that the operating voltage supplied to the A4988 Reprap falls within the specified range (8V to 35V). Operating the driver module outside this range can lead to malfunction or damage.

- Polarity and Wiring: Pay close attention to the polarity and wiring connections when connecting the A4988 Reprap to the motor and power supply. Incorrect wiring can result in short circuits or damage to the driver and other components.

- Electrostatic Discharge (ESD) Protection: Handle the A4988 Reprap and other sensitive electronic components with care to avoid damage from electrostatic discharge. Use appropriate ESD protection measures, such as grounding straps or mats, especially in dry or low-humidity environments.

- Configuring Microstepping: Ensure that the microstepping configuration (using jumper settings) matches your application requirements. Incorrect microstepping settings can affect motor performance and accuracy.

Usage tips of A4988 Reprap Stepper Motor Driver Module

- Adjust Motor Current: Set the motor current to an appropriate level using the surface mounted volume (potentiometer) on the module. Ensure that the motor current is sufficient to meet the torque requirements of your application without exceeding the driver's current rating.

Write Your Own Review

Please complete your information below to login.

Sign In

Create New Account