Product added to cart

400 Points Half Size Breadboard - 5.5x8.5cm

$0.3600

In stock

SKU

CAB-01-002

Volume discounts:

- +100 6 % $0.3400

- +1000 8 % $0.3300

- +5000 11 % $0.3200

- +10000 14 % $0.3100

Ships in 2-3 business days, then:

Free delivery in10-15 days by YunExpress on orders over $35.

Free delivery in5-7 days by DHL on orders over $200.

More shipping info

Shop with confidence Learn More

SYB-500 Breadboard - 200x240x8.5mm Previous

SYB-500 Breadboard - 200x240x8.5mm Previous

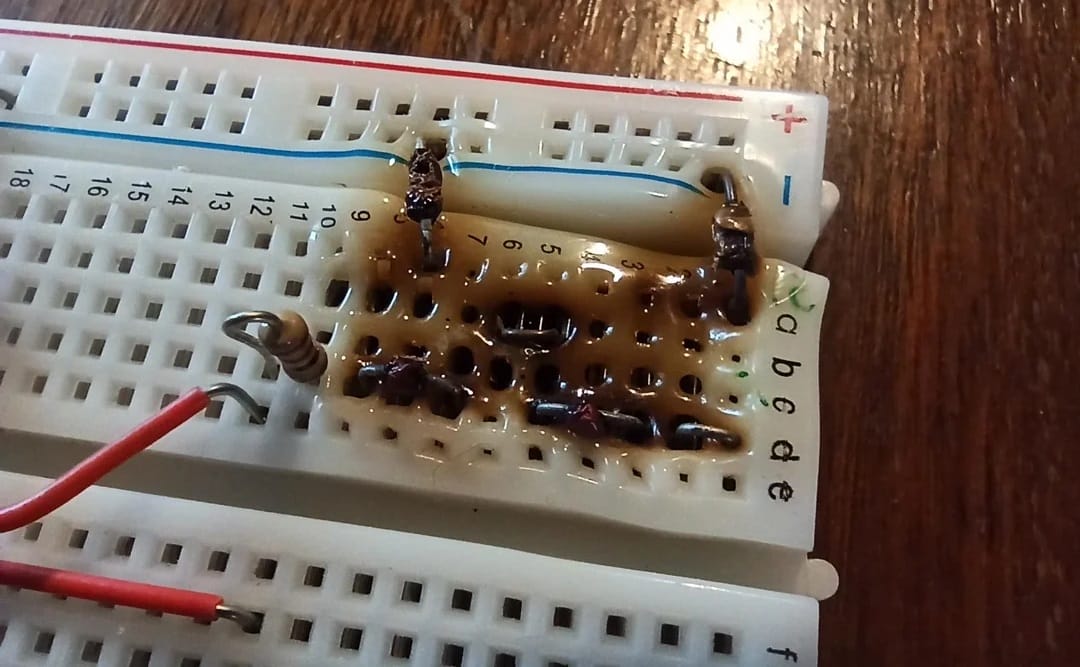

Mini Breadboard package contains an 85mmx55mm rectangle white breadboard that is made of ABS plastic material and phosphor bronze nickel-plated spring clips. A breadboard is a solderless board for temporary keeping the component and wiring circuit for test and experimenting the circuit in primary design stages. The electronic component legs can be inserted in the breadboard holes by gently pressing those fit in the hole and contact some in-line holes.

This half-size breadboard contains 400 holes that are divided into 2 groups of 300 Tie-Point Terminal Strip and 100 Tie-Point distribution strips. Since it does not require soldering, the breadboard can widely and easily be used in an experimental situation such as educational and R&D projects in the labs or universities to Trial and Error of the ideas. This breadboard is adopted with 2.54mm (about 0.1 in) pitch and 21 to 26 AWG wires standards.

Features of Half-Size 400 Tie Points Breadboard

Here are some key features and considerations for 400 Tie Points Breadboard:

- Completely reusable.

- Colored coordinates for easy component placement.

- Phosphor bronze nickel plated spring clips.

- Terminal Strip, Tie-point 300.

- Distribution strip, Tie-point 100.

- Pitch: 2.54mm

- Color: White

- Material: ABS Plastic

- Size: 8.5x5.5cm

One of the advantages of solderless breadboards is that they are reusable. Components and wires can be easily removed, allowing for quick modifications and redesigns.

To use breadboards, you must get some suitable jumper wires.

The maximum current that a breadboard can handle

Breadboards are generally designed for low to moderate current applications, typically in the range of a few hundred milliamps to a few amps. Breadboards use metal contacts (usually made of springy metal strips) to make connections between components. These contacts introduce some resistance, and at higher currents, this can result in voltage drops and increased heat.

For better heat dissipation, distribute high-current components across multiple rows and columns on the breadboard to avoid concentration of heat in one area.

Use cases of 400 points Half Size Breadboard

- Rapid Prototyping: Breadboards are excellent for quickly building and testing circuits during the prototyping phase of a project. They allow engineers and hobbyists to experiment with different components and configurations without committing to a permanent soldered design.

- Temporary or One-Time Projects: For projects where a permanent soldered circuit is not necessary, a breadboard offers a convenient and temporary solution. Once the prototype is validated, a more permanent circuit can be designed and assembled.

- Testing and Debugging: When troubleshooting or debugging a circuit, a breadboard allows for quick modifications and testing of different components or connections. This flexibility can significantly speed up the debugging process.

- No Soldering Required: Breadboards are solderless, making them accessible to individuals who may not have soldering skills or equipment. This is especially useful for beginners or those working on small projects.

- Component Interfacing: When working with various electronic components such as resistors, capacitors, and integrated circuits, a breadboard provides a platform for easy connection and integration of these components into a functional circuit.

- Design Validation: Before committing to a final circuit design, engineers often use breadboards to validate their ideas. This allows them to test the functionality of the circuit and make necessary adjustments before moving on to the final implementation.

- Complex Circuit Exploration: Breadboards are especially useful when working on more complex circuits that involve multiple components and connections. They provide a neat and organized way to prototype intricate designs.

- Low-Frequency Analog Circuits: Breadboards are suitable for low-frequency analog circuits. However, for high-frequency circuits or sensitive analog designs, factors like parasitic capacitance and inductance on a breadboard may affect performance, and a more specialized prototyping method might be preferred.

Write Your Own Review

Please complete your information below to login.

Sign In

Create New Account